Today I brought the cylinder-head and cylinder-block to “Rombouts revisie” in goirle.

The measured clearance:

- Crankshaft STD with 15/100 mm clearance

- Inlet Camshaft STD with no visible play

- Outlet Camshaft STD with no visible play

- Piston 1 STD with 15/100 mm clearance

- Piston 2 STD with 15/100 mm clearance

- Piston 3 STD with 15/100 mm clearance

- Piston 4 STD with 15/100 mm clearance

- Piston 5 STD with 15/100 mm clearance (after drilling to 75/100 mm still corrosion visable)

- Piston 6 STD with 25/100 mm clearance (after drilling to 50/100 mm still corrosion visable)

- To match play on the valve guides

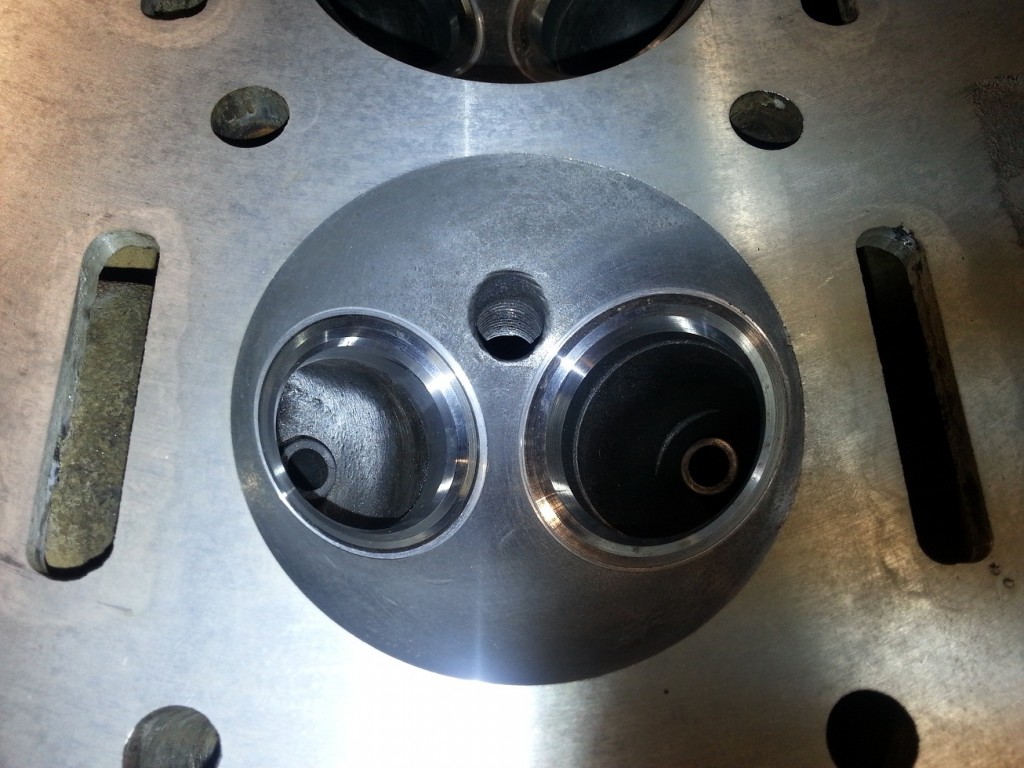

- Valve seats are worn and will be replaced by unleaded fuel types

.010″ = 10/1000″ = 0,25 mm = 25/100 mm

.020″ = 20/1000″ = 0,50 mm = 50/100 mm

Before the actual revision started they executed a cylinder head water pressure test to discover possible water leakage. (Due to the visible corrosion in the cylinder head) The conclusion was that it already started to leak inside combustion chamber 5 at a very low water pressure level. The advise was to look for a different cylinder head due to the high corrosion level in combustion chamber 4, 5 and 6. So I brought my XK120 head for the same test and although the water channels where no so good, the combustion chambers where much much better. Because the head between the XK120 and XK140 are technically equal (except for the number stamped into the casting) I decided to take the XK120 head.

The valves from both heads (24 in total) are not usable anymore because;

- 10 pieces are damaged by corrosion

- 7 pieces are shortened to compensate the excessive valve seat wear.

Work for the revision company:

- Re-sleeve cylinder wall 5 and 6

- Drill all cylinders to +020

- Flattening of the cylinder block

- Water pressure tests on two different XK cylinder heads

- Replace all valve seats with unleaded fuel types

- Replace all valve guides

- Flattening of the cylinder head

- Welding all damaged water channels in the cylinder head (12 x)

The discoloring around the water channels shows what has been welded

In the mean time I ordered the following new parts:

- 6 Pistons oversize +20

- 6 inlet valves

- 6 exhaust valves

- Crankshaft bearing

- Thrust bearing

- Big end bearings

- Camshaft bearing

- Bottom gasket set (including oil seals)

- Top gasket set (including oil seals)

All preparation has been finished (10 october 2014), the assembly process can now be started.