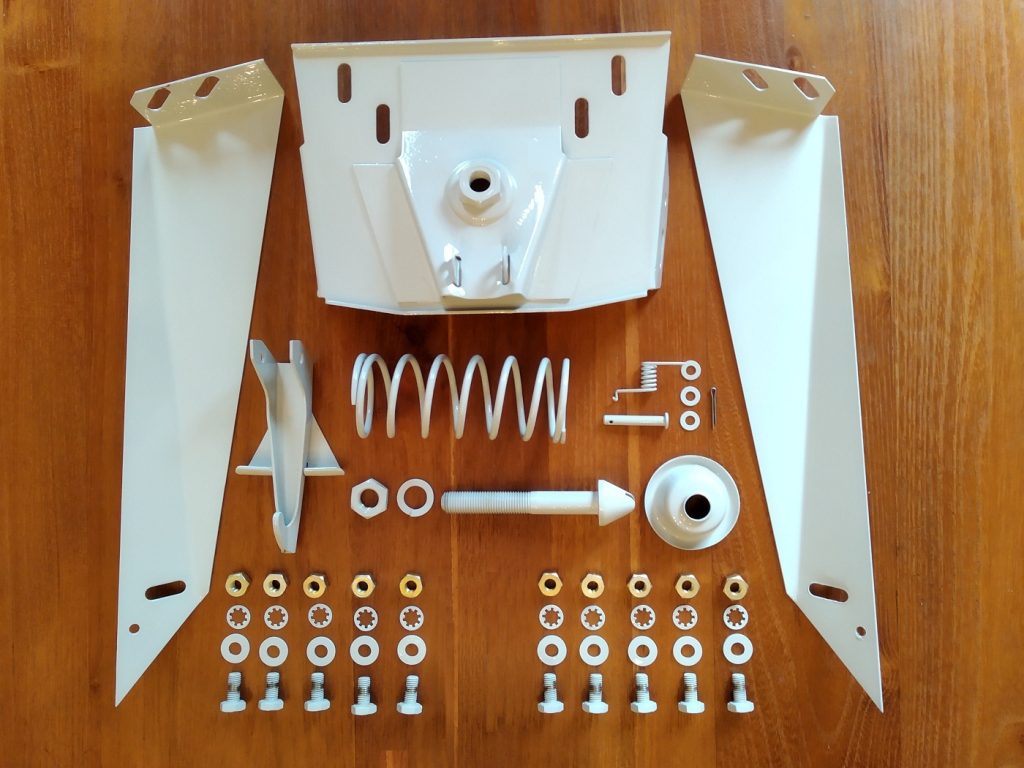

During the restoration process I found out that a number of parts where missing or the mounted parts where incorrect.

A lot of parts are still available in the reproduction market but I prefer second hand original vintage parts instead. Here is a list with the most important parts still missing:

- 1 x Anti-Blow-Back Valve in Starting Pipe (C4204, Parts manual 2, F-79)

- 1 x Spring, tension, for Anti-Blow-Back Valve (C7470, Parts manual 2, F80)

- 1 x Sleeve over Tension Spring (C8455, Parts manual 2, F81)

- 1 x Lever on Operating Shaft (C2483, Parts manual 5,N-12)

- 1 x Clutch Pedal (C8878, Parts manual 5, N-16)